On March 20, the 2024 China Flash Memory Market Summit (hereinafter referred to as "CFMS2024") was successfully held in Shenzhen. With the theme of "Storage Cycle Unlocks Potential", this year's CFMS2024 brought together the global storage industry chain and terminal application companies to discuss new trends. Opportunities under market conditions.

At the CFMS2024 Summit, Longsys Chairman and General Manager Cai Huabo delivered a speech titled "Breaking through the Curse of Storage Module Management", sharing the company's strategy for comprehensive transformation and upgrading from a "storage module factory" to a "semiconductor storage brand enterprise" layout, and how to realize the model leap from sales model to core service.

(Chairman and General Manager of Longsys Cai Huabo)

Cai Huabo gave an in-depth analysis of the current operating pain points faced by storage module factories. With the intensification of market competition and inherent bottlenecks in business models, the current mainstream business models of traditional storage module factories are facing difficulties in breaking through the revenue ceiling of US$2 billion. To this end, Longsys has carried out innovative layout and transformation and upgrading in multiple dimensions such as technology, products, supply chain integration, brand and business model to break through the operating curse of storage module factories.

R&D, packaging and testing integration

Consolidate the vertical integration strength of semiconductor storage technology

-Self-developed SLC NAND Flash chip + main control chip-

Cai Huabo said that Longsys insists on independent research and development and invests in core technologies. It has now mastered the design capabilities of SLC NAND Flash, MLC NAND Flash, and NOR Flash chips, especially in SLC NAND Flash chips, and has achieved large-scale mass production. The breakthrough of Flash's self-developed chip can not only better serve the storage needs of existing customers, but also help Longsys gain a more comprehensive and in-depth understanding of Flash underlying technology and chip manufacturing technology, further improving the company's overall storage products quality, as well as comprehensive competitiveness in the storage field.

The main control chip plays a vital role in storage products, and its importance is self-evident. In the second half of 2023, the company's subsidiary Huiyi Microelectronics (WiseMem) launched WM6000 (eMMC 5.1 controller) and WM5000 (SD 6.1 memory card controller) self-developed main control chips. Both products use self-developed LDPC algorithms and Samsung's 28nm advanced process technology leads the industry in performance. This year, two self-developed main control chips have fully entered the stage of large-scale productization.

From NAND Flash chips to cutting-edge firmware algorithms to main control chips, Longsys has achieved relatively complete independent design capabilities for memory chips, laying a solid foundation for the company's continued development and innovation in the storage industry. At the same time, Longsys will maintain an open and cooperative attitude, continue to strengthen in-depth cooperation and complementary cooperation with multiple main control solution manufacturers in the industry, fully meet the diverse needs of customers, and work together to create better storage products.

-In-house packaging and testing manufacturing-

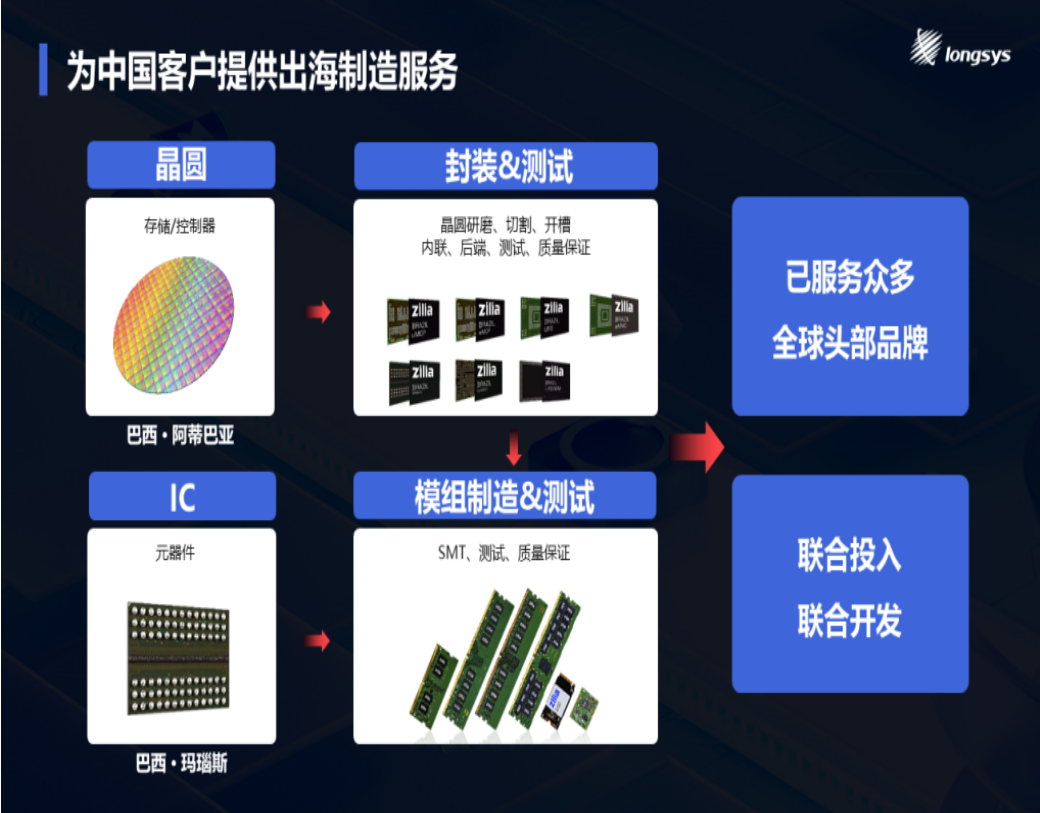

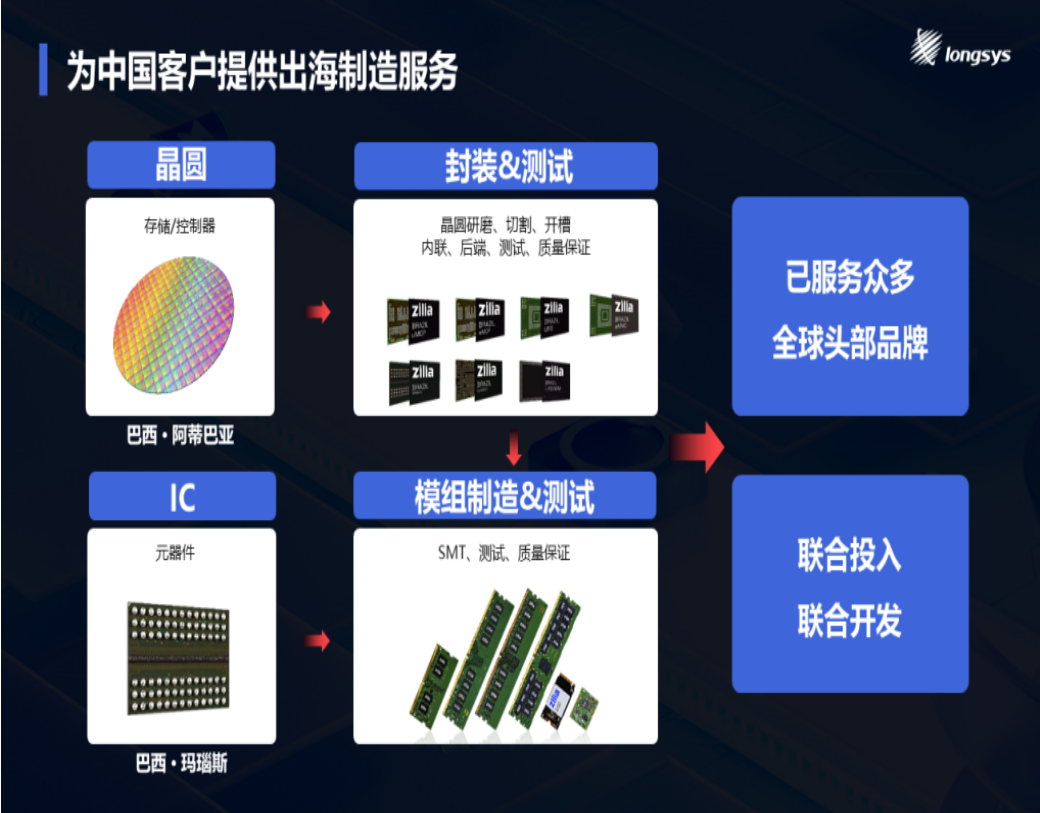

With the acquisition of leading packaging, testing and manufacturing bases such as Yuancheng Suzhou and Zilia, as well as the self-built Zhongshan data center storage line, Longsys has built its own high-end packaging, testing and manufacturing center, all-round Lay out a domestic and overseas dual-cycle supply chain system to realize the integration of R&D, packaging and testing in various industrial chain links from chip design, software and hardware design, wafer processing, packaging and testing to production and manufacturing, further consolidating the company's vertical integration strength in semiconductor storage technology. At present, Zilia has successfully provided high-quality services to many leading brands around the world. At the same time, it actively provides overseas manufacturing solutions to Chinese customers, helping customers demonstrate excellent competitiveness in the global market. At present, Yuancheng Suzhou has successfully undertaken the packaging, testing and manufacturing tasks of some of the company's embedded storage and industrial-grade and automotive-grade storage, and all work is progressing well.

Advanced technology of dual-brand high-energy storage products inspires the awakening of storage power

Longsys introduced in depth and demonstrated a series of innovative technologies and products in the field of storage applications of the company's two major brands Lexar and FORESEE at the summit, comprehensively demonstrating the company's achievements in consumer storage, embedded storage, and industrial planning. / Active exploration and breakthroughs in multiple application scenarios such as car-level storage and enterprise-level data storage.

-Lexar innovative high-end memory card-

1TB NM Card

2TB microSD Card

205MB/s reading speed 3.0 SD Card

Since the successful release of the 512GB capacity NM Card at the end of last year, Lexar has once again made a product breakthrough, taking the lead in launching a 1TB ultra-large capacity NM Card version, which can be adapted to the card slots of many Hongmeng OS mobile phones/tablets to provide users with storage Space expansion. This product uses the WM6000 self-developed main control that is compatible with the eMMC protocol, and uses the advanced packaging process of Yuancheng Suzhou's ultra-thin NAND stacking technology to successfully achieve productization. With the promotion and popularization of China's storage standards and NM Card protocol by the ITMA Association, as well as the continuous iterative upgrade of terminal equipment, more models will support this ultra-large capacity NM Card in the future, providing users with more efficient mobile phone expansion solutions. .

Lexar has also launched two industry-leading high-end memory cards for gaming and image storage applications. Among them, the 2TB large-capacity microSD Card relies on advanced 12Die stacking technology and ultra-thin grinding and cutting technology to overcome the bottleneck of packaging technology. On the basis of strictly following microSD size standards, it can achieve higher integration and release greater storage. space. Another SD 3.0 memory card has become the product focus with high-speed reading and writing of 205MB/s / 150MB/s, and its performance is leading the industry level. This memory card adopts the innovative 4Plane direct writing architecture to achieve dual-effect acceleration of SDIO and NAND-IO. Both products are equipped with WM5000 self-developed main control and self-developed firmware algorithms, bringing users a smoother and more efficient memory card experience.

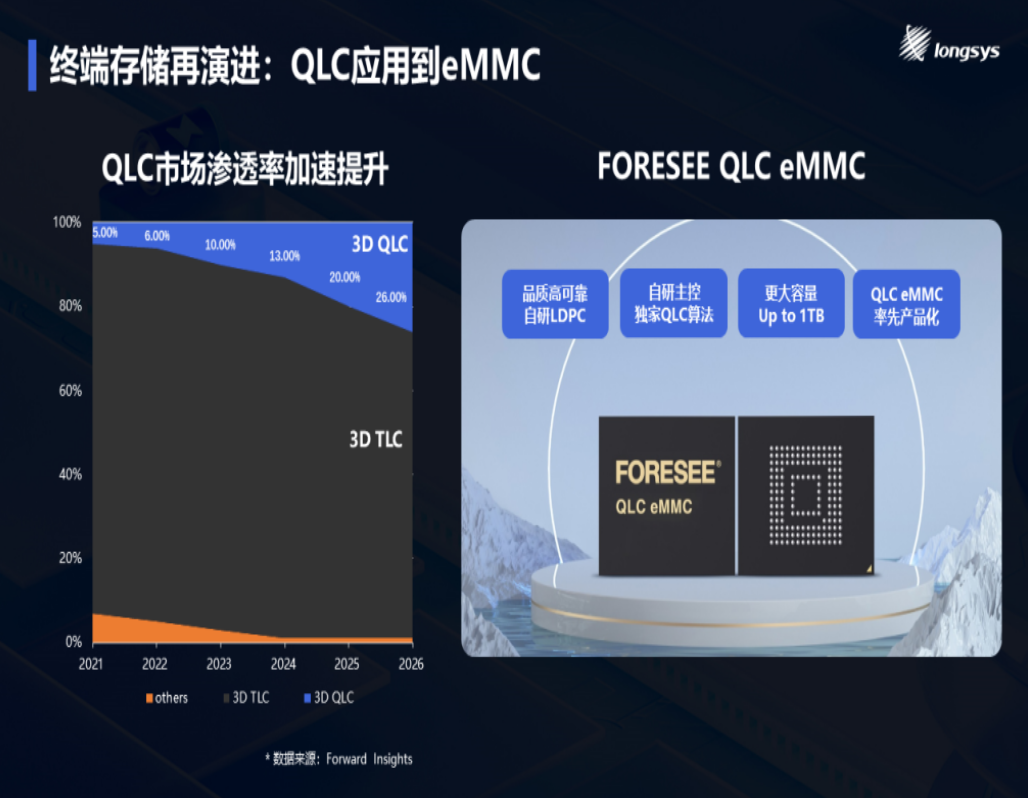

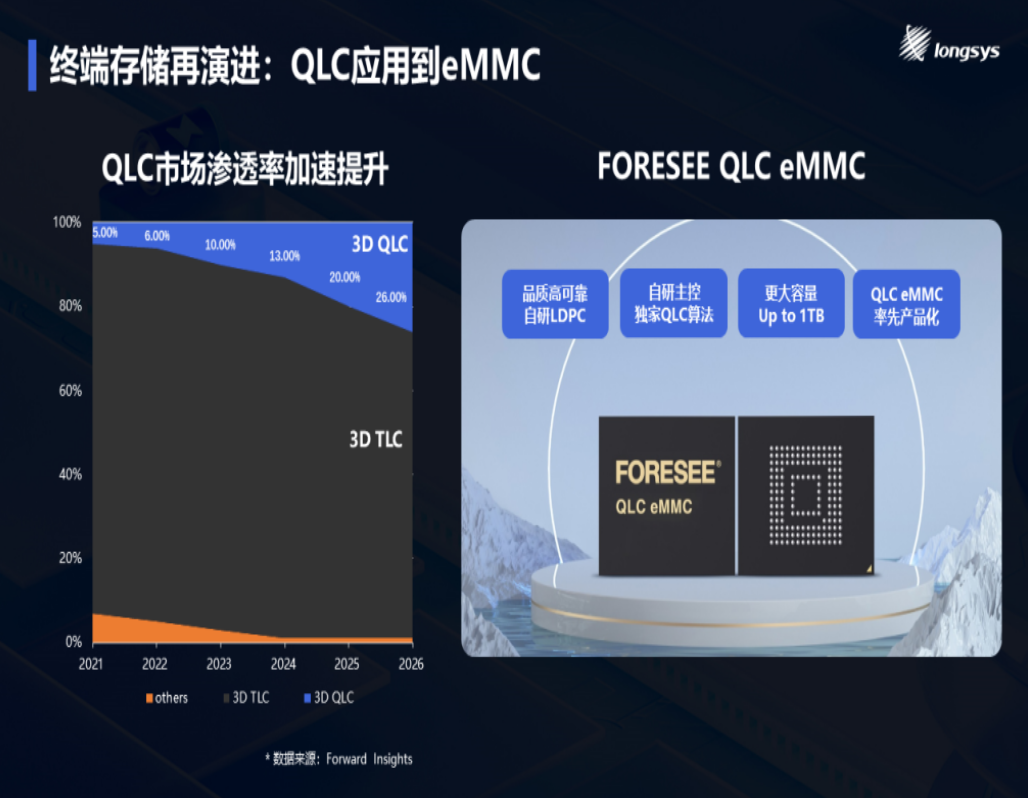

-FORESEE QLC eMMC-

As the QLC NAND Flash market penetration rate rises rapidly, Longsys has grasped the market trend and taken the lead in applying advanced 3D QLC technology to eMMC products, launching FORESEE QLC eMMC to meet the "cost reduction and capacity expansion" needs of terminal applications. This product is also developed based on the WM6000 self-developed main control, using a unique QLC algorithm and self-developed firmware. After continuous technical optimization by the company's R&D team, it has passed a number of internal rigorous tests and has reached mass production status. In terms of performance and reliability, this product is already comparable to TLC eMMC; in terms of capacity, in addition to the 512GB specification launched this time, Longsys also has the technical capabilities to achieve a larger capacity of 1TB and will provide the market with More diverse choices.

In order to meet the growing demand for 5G mobile phone storage capacity, the company's embedded storage product FORESEE UFS2.2 has officially started large-scale mass production and shipment, providing high-performance, large-capacity storage solutions for the smart terminal market. At present, Longsys has built a comprehensive layout in the field of embedded storage that combines composite storage and separated storage, and has met many strict vehicle regulatory system standards such as AEC-Q100, IATF16949, PPAP, etc., empowering industry innovation .

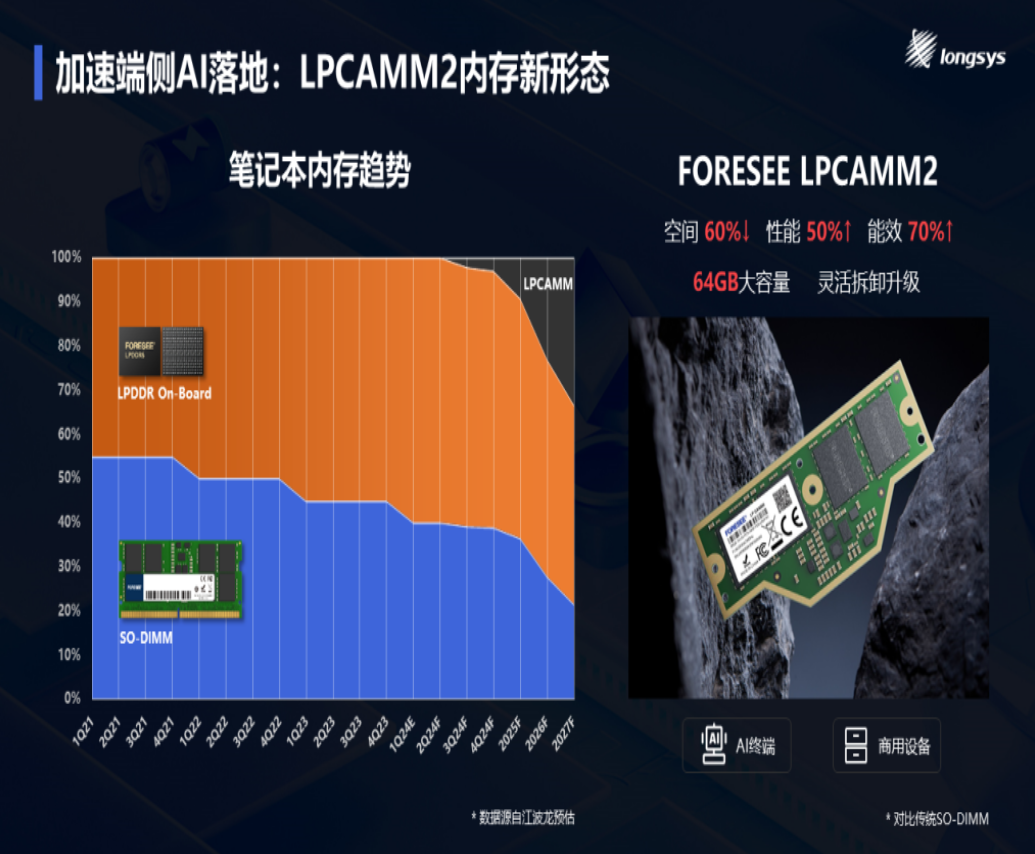

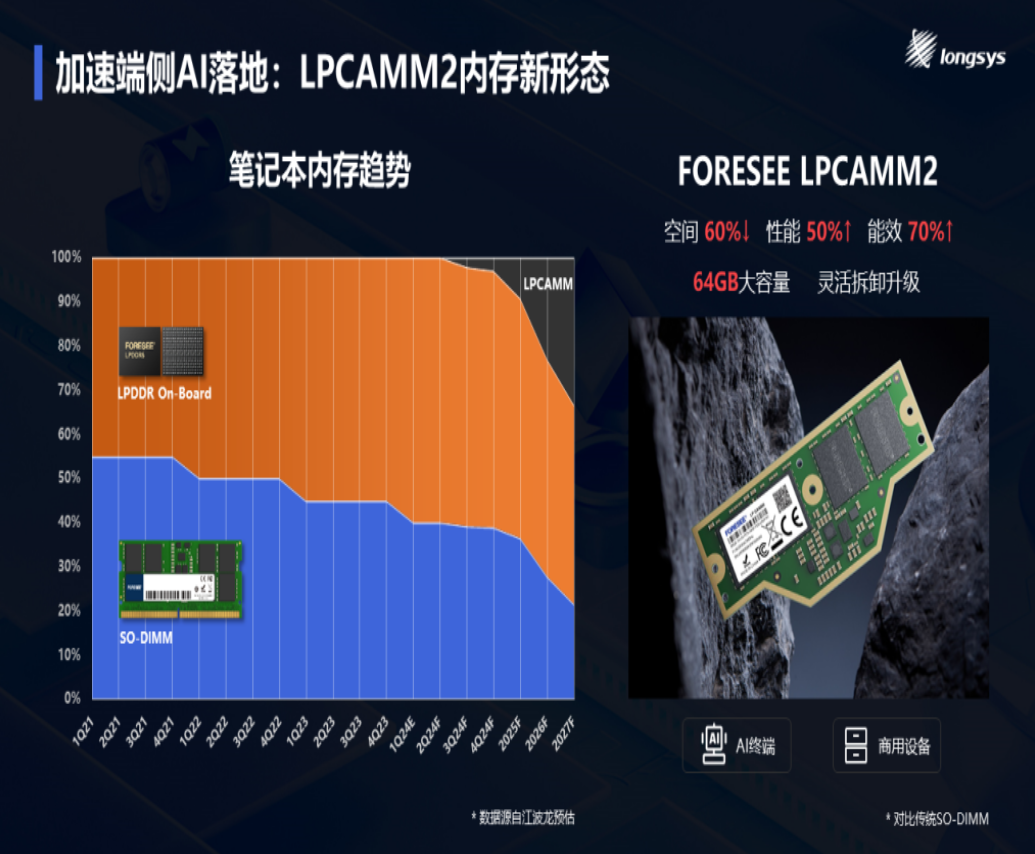

-FORESEE LPCAMM2 new memory form-

-FORESEE LPCAMM2 new memory form-

At this CFMS summit, Longsys also released FORESEE LPCAMM2 (16GB/32GB/64GB). With its unique 128bit width design, this product has achieved a new breakthrough in memory form and is expected to open up PC and mobile phone storage application scenarios. Compared with the traditional SODIMM form, LPCAMM2 has reduced its size by nearly 60%, increased energy efficiency by nearly 70%, and reduced power consumption by nearly 50%. At the same time, its speed is as high as 9600Mbps, far exceeding the 6400Mbps of DDR5 SODIMM, breaking the traditional memory speed. bottleneck. Compared with on board LPDDR products, LPCAMM2's flexible modular appearance not only has excellent scalability, but also provides higher maintainability for terminal equipment, helping customers reduce after-sales difficulties and achieve more convenient upgrades. The innovative form of LPCAMM2 brings a dramatic improvement in performance and energy efficiency to application scenarios that have strict requirements on small size, such as AI terminals, commercial equipment, and ultra-thin notebooks, and is expected to lead the mainstream direction of memory development. In the future, the capacity of FORESEE LPCAMM2 memory products will gradually increase with technological development and customer demand.

-FORESEE CXL 2.0 memory expansion module-

-FORESEE CXL 2.0 memory expansion module-

In recent years, Longsys has embarked on a heavy investment model and continued to increase its efforts in the field of enterprise-level storage R&D, creating an eSSD+RDIMM product application portfolio and a dedicated data center storage manufacturing line. It has now broken through industry benchmark customers in multiple fields and achieved large-scale Volume production and delivery.

With the rapid development of AI, computing-intensive workloads have placed unprecedentedly high demands on low-latency and high-bandwidth storage. Compute Express Link® (CXL®) interconnect technology opens new ways to improve data center performance and efficiency. Driven by cutting-edge technology trends, Longsys took the lead in releasing and demonstrating on-site its first FORESEE CXL 2.0 memory expansion module designed with self-developed architecture at this CFMS2024, which supports memory pool sharing and brings new possibilities to enterprise-level application scenarios. breakthrough. Through unique stacking technology, this product can achieve a large capacity of 128GB based on 16Gb SDP particles, achieving a significant cost reduction compared to the same period in the industry.

FORESEE CXL 2.0 memory expansion module is developed based on DDR5 DRAM, supports PCIe 5.0×8 interface, and has a theoretical bandwidth of up to 32GB/s. It can achieve seamless connection with backplanes and server motherboards that support CXL specifications and E3.S interfaces, and reduce expensive Memory costs and idle memory resources can be greatly improved, thereby effectively expanding the server's memory capacity and improving bandwidth performance, helping to unleash the potential of HPC, cloud computing, AI and other application scenarios.

In terms of capacity, the FORESEE CXL 2.0 memory expansion module can achieve a variety of capacity options, including 64GB, 128GB, 192GB and 512GB under development, which fully meets the storage needs of users in different computing applications. It is worth mentioning that compared with the mainstream 32GB and 64GB similar products on the market, the FORESEE CXL 2.0 memory expansion module shows significant advantages in capacity. Currently, FORESEE CXL 2.0 memory expansion module and LPCAMM2 products are ready for full-scale mass production and will be put into production in an orderly manner to meet market demand.

TCM innovative business model

Improve the comprehensive competitiveness of the storage industry

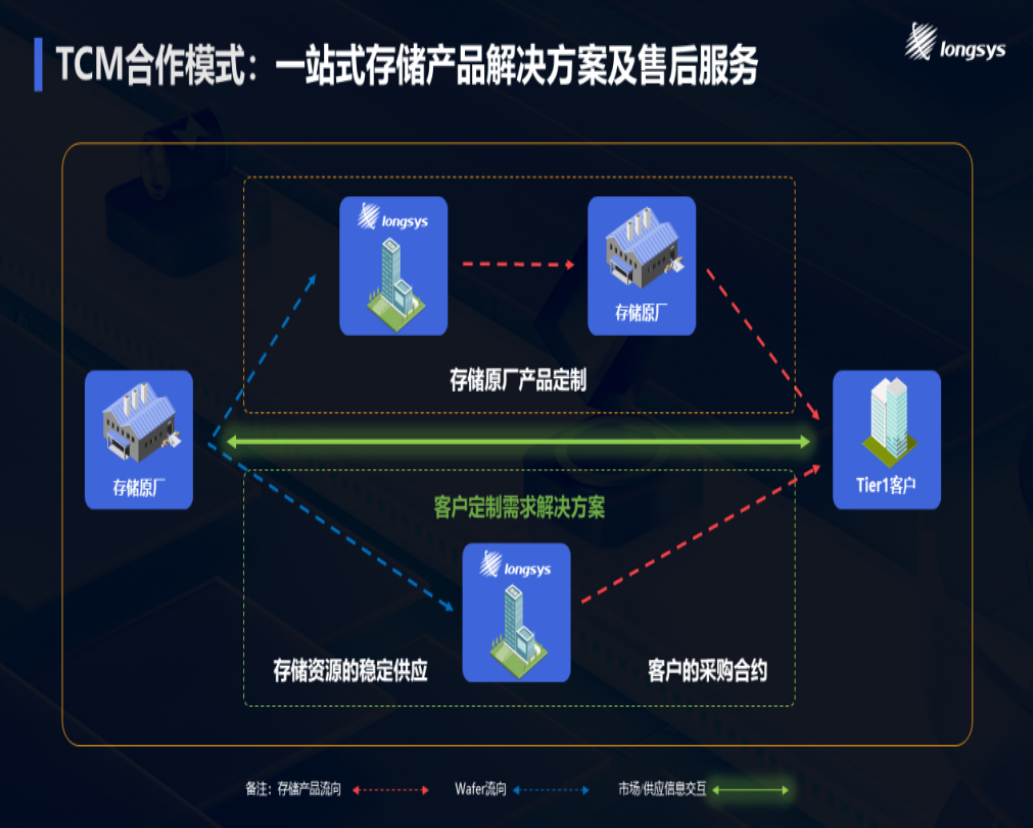

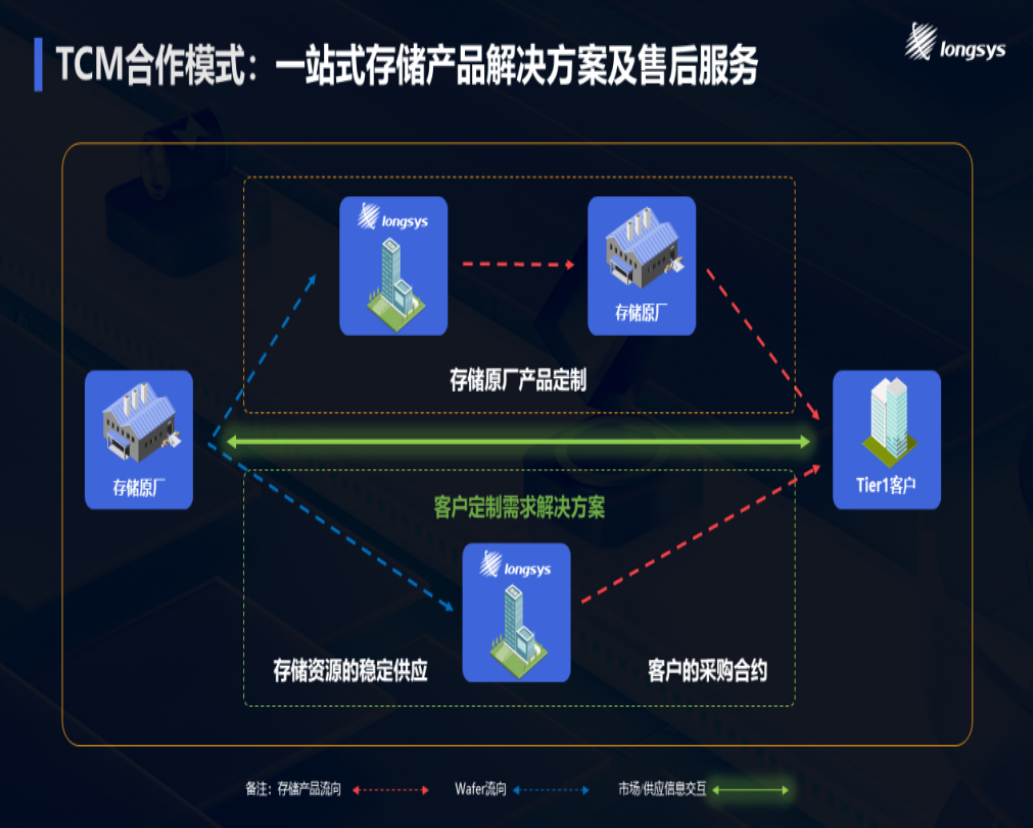

Cai Huabo emphasized that Longsys is undergoing a major upgrade of its business model. In order to provide Tier 1 customers with more stable supply and efficient customized storage solution services, Longsys collaborates with upstream storage wafer fabs to jointly propose a transformation from the traditional product sales model to a TCM (Technologies Contract Manufacturer, Technology Contract Manufacturing) cooperation model. upgrade.

Under the traditional sales model, storage module manufacturers first purchase wafers from the original storage factory, and then sell them to end customers after going through R&D, design, packaging, testing and manufacturing. The complexity of the intermediate links between the upstream original manufacturers and downstream end customers has led to "disconnections" in communication, and it is also difficult to efficiently match the downstream application market's demand for diversified, customized, and innovative storage products. Module factories also need to purchase large amounts of wafers from original factories in advance for reserve, and face challenges such as huge price fluctuations brought about by the industry cycle.

The TCM (Technical Contract Manufacturing) cooperation model enables efficient and direct supply and demand information communication between upstream storage wafer original manufacturers and downstream Tier1 core customers. Based on deterministic supply and demand contracts, Longsys focuses on the advantages of the storage solution service platform and integrates storage master control , firmware custom development, high-end packaging and testing technology, after-sales service, brand and intellectual property and other capabilities, based on the product needs of upstream storage wafer fabs or downstream Tier1 customers, we can efficiently complete one-stop delivery of storage products. This will improve the efficiency and effectiveness of the storage industry chain from original factories, product development, packaging and testing, product manufacturing to industry applications.

The TCM model aims to create a new anchoring relationship between supply and demand, upgrading the collaborative operation of the industrial chain from the traditional "one-way simplex mode" to a "two-way duplex mode". Under this mode, the original factory can communicate with downstream Tier 1 in a more timely manner Customers conduct information docking, observe real market demand, plan production capacity and resource pricing according to market demand, and focus more on wafer process innovation and production capacity improvement in terms of technology investment, while Longsys will focus on subsequent storage product research and development, customer customization, Integrate packaging, testing, manufacturing and delivery. At the same time, downstream Tier 1 customers can obtain a stable supply of storage resources and the opportunity to deeply participate in the pricing mechanism based on the aforementioned docking and exchange mechanism with the original manufacturer. Longsys will focus on providing customers with more flexible, open, transparent and innovative customization Store products and services to optimally meet the business demands of original manufacturers and Tier1 customers.

As a leading domestic semiconductor storage brand enterprise, Longsys can provide comprehensive industry services throughout the entire chain from memory chip research and development to packaging, testing and manufacturing, and has industrial advantages and accumulation in multiple dimensions such as technology, manufacturing, services, intellectual property, quality, and capital. , has enough strength to integrate the complex intermediate links from upstream original manufacturers to downstream applications, while assisting and serving original manufacturers to improve their operating efficiency, flexibility and customer satisfaction, while jointly providing more stable storage for downstream application Tier1 end customers Resource supply guarantee, more flexible product customization and technical support, and more complete comprehensive services, thereby opening up multiple links in the value chain, jointly building storage resource transparency, technology manufacturing value, comprehensive service customization, and maximizing delivery efficiency. transaction costs minimized

A new cooperation ecosystem to enhance the comprehensive competitiveness of the storage industry.

Customized business operates independently

Service precise focus

Cai Huabo pointed out that Longsys’ original traditional customization and sales business will be fully undertaken and independently operated by Mestor, a wholly-owned subsidiary, to further optimize the company’s overall business layout and achieve multi-point collaboration and efficient development. . Maxdu Electronics focuses on the R&D, manufacturing and sales of general-purpose memories. It has diversified product lines and independent manufacturing capabilities, and provides professional and efficient OEM/ODM/DMS storage services to domestic and foreign customers.

On March 20, the 2024 China Flash Memory Market Summit (hereinafter referred to as "CFMS2024") was successfully held in Shenzhen. With the theme of "Storage Cycle Unlocks Potential", this year's CFMS2024 brought together the global storage industry chain and terminal application companies to discuss new trends. Opportunities under market conditions.

At the CFMS2024 Summit, Longsys Chairman and General Manager Cai Huabo delivered a speech titled "Breaking through the Curse of Storage Module Management", sharing the company's strategy for comprehensive transformation and upgrading from a "storage module factory" to a "semiconductor storage brand enterprise" layout, and how to realize the model leap from sales model to core service.

(Chairman and General Manager of Longsys Cai Huabo)

Cai Huabo gave an in-depth analysis of the current operating pain points faced by storage module factories. With the intensification of market competition and inherent bottlenecks in business models, the current mainstream business models of traditional storage module factories are facing difficulties in breaking through the revenue ceiling of US$2 billion. To this end, Longsys has carried out innovative layout and transformation and upgrading in multiple dimensions such as technology, products, supply chain integration, brand and business model to break through the operating curse of storage module factories.

R&D, packaging and testing integration

Consolidate the vertical integration strength of semiconductor storage technology

-Self-developed SLC NAND Flash chip + main control chip-

Cai Huabo said that Longsys insists on independent research and development and invests in core technologies. It has now mastered the design capabilities of SLC NAND Flash, MLC NAND Flash, and NOR Flash chips, especially in SLC NAND Flash chips, and has achieved large-scale mass production. The breakthrough of Flash's self-developed chip can not only better serve the storage needs of existing customers, but also help Longsys gain a more comprehensive and in-depth understanding of Flash underlying technology and chip manufacturing technology, further improving the company's overall storage products quality, as well as comprehensive competitiveness in the storage field.

The main control chip plays a vital role in storage products, and its importance is self-evident. In the second half of 2023, the company's subsidiary Huiyi Microelectronics (WiseMem) launched WM6000 (eMMC 5.1 controller) and WM5000 (SD 6.1 memory card controller) self-developed main control chips. Both products use self-developed LDPC algorithms and Samsung's 28nm advanced process technology leads the industry in performance. This year, two self-developed main control chips have fully entered the stage of large-scale productization.

From NAND Flash chips to cutting-edge firmware algorithms to main control chips, Longsys has achieved relatively complete independent design capabilities for memory chips, laying a solid foundation for the company's continued development and innovation in the storage industry. At the same time, Longsys will maintain an open and cooperative attitude, continue to strengthen in-depth cooperation and complementary cooperation with multiple main control solution manufacturers in the industry, fully meet the diverse needs of customers, and work together to create better storage products.

-In-house packaging and testing manufacturing-

With the acquisition of leading packaging, testing and manufacturing bases such as Yuancheng Suzhou and Zilia, as well as the self-built Zhongshan data center storage line, Longsys has built its own high-end packaging, testing and manufacturing center, all-round Lay out a domestic and overseas dual-cycle supply chain system to realize the integration of R&D, packaging and testing in various industrial chain links from chip design, software and hardware design, wafer processing, packaging and testing to production and manufacturing, further consolidating the company's vertical integration strength in semiconductor storage technology. At present, Zilia has successfully provided high-quality services to many leading brands around the world. At the same time, it actively provides overseas manufacturing solutions to Chinese customers, helping customers demonstrate excellent competitiveness in the global market. At present, Yuancheng Suzhou has successfully undertaken the packaging, testing and manufacturing tasks of some of the company's embedded storage and industrial-grade and automotive-grade storage, and all work is progressing well.

Advanced technology of dual-brand high-energy storage products inspires the awakening of storage power

Longsys introduced in depth and demonstrated a series of innovative technologies and products in the field of storage applications of the company's two major brands Lexar and FORESEE at the summit, comprehensively demonstrating the company's achievements in consumer storage, embedded storage, and industrial planning. / Active exploration and breakthroughs in multiple application scenarios such as car-level storage and enterprise-level data storage.

-Lexar innovative high-end memory card-

1TB NM Card

2TB microSD Card

205MB/s reading speed 3.0 SD Card

Since the successful release of the 512GB capacity NM Card at the end of last year, Lexar has once again made a product breakthrough, taking the lead in launching a 1TB ultra-large capacity NM Card version, which can be adapted to the card slots of many Hongmeng OS mobile phones/tablets to provide users with storage Space expansion. This product uses the WM6000 self-developed main control that is compatible with the eMMC protocol, and uses the advanced packaging process of Yuancheng Suzhou's ultra-thin NAND stacking technology to successfully achieve productization. With the promotion and popularization of China's storage standards and NM Card protocol by the ITMA Association, as well as the continuous iterative upgrade of terminal equipment, more models will support this ultra-large capacity NM Card in the future, providing users with more efficient mobile phone expansion solutions. .

Lexar has also launched two industry-leading high-end memory cards for gaming and image storage applications. Among them, the 2TB large-capacity microSD Card relies on advanced 12Die stacking technology and ultra-thin grinding and cutting technology to overcome the bottleneck of packaging technology. On the basis of strictly following microSD size standards, it can achieve higher integration and release greater storage. space. Another SD 3.0 memory card has become the product focus with high-speed reading and writing of 205MB/s / 150MB/s, and its performance is leading the industry level. This memory card adopts the innovative 4Plane direct writing architecture to achieve dual-effect acceleration of SDIO and NAND-IO. Both products are equipped with WM5000 self-developed main control and self-developed firmware algorithms, bringing users a smoother and more efficient memory card experience.

-FORESEE QLC eMMC-

As the QLC NAND Flash market penetration rate rises rapidly, Longsys has grasped the market trend and taken the lead in applying advanced 3D QLC technology to eMMC products, launching FORESEE QLC eMMC to meet the "cost reduction and capacity expansion" needs of terminal applications. This product is also developed based on the WM6000 self-developed main control, using a unique QLC algorithm and self-developed firmware. After continuous technical optimization by the company's R&D team, it has passed a number of internal rigorous tests and has reached mass production status. In terms of performance and reliability, this product is already comparable to TLC eMMC; in terms of capacity, in addition to the 512GB specification launched this time, Longsys also has the technical capabilities to achieve a larger capacity of 1TB and will provide the market with More diverse choices.

In order to meet the growing demand for 5G mobile phone storage capacity, the company's embedded storage product FORESEE UFS2.2 has officially started large-scale mass production and shipment, providing high-performance, large-capacity storage solutions for the smart terminal market. At present, Longsys has built a comprehensive layout in the field of embedded storage that combines composite storage and separated storage, and has met many strict vehicle regulatory system standards such as AEC-Q100, IATF16949, PPAP, etc., empowering industry innovation .

-FORESEE LPCAMM2 new memory form-

-FORESEE LPCAMM2 new memory form-

At this CFMS summit, Longsys also released FORESEE LPCAMM2 (16GB/32GB/64GB). With its unique 128bit width design, this product has achieved a new breakthrough in memory form and is expected to open up PC and mobile phone storage application scenarios. Compared with the traditional SODIMM form, LPCAMM2 has reduced its size by nearly 60%, increased energy efficiency by nearly 70%, and reduced power consumption by nearly 50%. At the same time, its speed is as high as 9600Mbps, far exceeding the 6400Mbps of DDR5 SODIMM, breaking the traditional memory speed. bottleneck. Compared with on board LPDDR products, LPCAMM2's flexible modular appearance not only has excellent scalability, but also provides higher maintainability for terminal equipment, helping customers reduce after-sales difficulties and achieve more convenient upgrades. The innovative form of LPCAMM2 brings a dramatic improvement in performance and energy efficiency to application scenarios that have strict requirements on small size, such as AI terminals, commercial equipment, and ultra-thin notebooks, and is expected to lead the mainstream direction of memory development. In the future, the capacity of FORESEE LPCAMM2 memory products will gradually increase with technological development and customer demand.

-FORESEE CXL 2.0 memory expansion module-

-FORESEE CXL 2.0 memory expansion module-

In recent years, Longsys has embarked on a heavy investment model and continued to increase its efforts in the field of enterprise-level storage R&D, creating an eSSD+RDIMM product application portfolio and a dedicated data center storage manufacturing line. It has now broken through industry benchmark customers in multiple fields and achieved large-scale Volume production and delivery.

With the rapid development of AI, computing-intensive workloads have placed unprecedentedly high demands on low-latency and high-bandwidth storage. Compute Express Link® (CXL®) interconnect technology opens new ways to improve data center performance and efficiency. Driven by cutting-edge technology trends, Longsys took the lead in releasing and demonstrating on-site its first FORESEE CXL 2.0 memory expansion module designed with self-developed architecture at this CFMS2024, which supports memory pool sharing and brings new possibilities to enterprise-level application scenarios. breakthrough. Through unique stacking technology, this product can achieve a large capacity of 128GB based on 16Gb SDP particles, achieving a significant cost reduction compared to the same period in the industry.

FORESEE CXL 2.0 memory expansion module is developed based on DDR5 DRAM, supports PCIe 5.0×8 interface, and has a theoretical bandwidth of up to 32GB/s. It can achieve seamless connection with backplanes and server motherboards that support CXL specifications and E3.S interfaces, and reduce expensive Memory costs and idle memory resources can be greatly improved, thereby effectively expanding the server's memory capacity and improving bandwidth performance, helping to unleash the potential of HPC, cloud computing, AI and other application scenarios.

In terms of capacity, the FORESEE CXL 2.0 memory expansion module can achieve a variety of capacity options, including 64GB, 128GB, 192GB and 512GB under development, which fully meets the storage needs of users in different computing applications. It is worth mentioning that compared with the mainstream 32GB and 64GB similar products on the market, the FORESEE CXL 2.0 memory expansion module shows significant advantages in capacity. Currently, FORESEE CXL 2.0 memory expansion module and LPCAMM2 products are ready for full-scale mass production and will be put into production in an orderly manner to meet market demand.

TCM innovative business model

Improve the comprehensive competitiveness of the storage industry

Cai Huabo emphasized that Longsys is undergoing a major upgrade of its business model. In order to provide Tier 1 customers with more stable supply and efficient customized storage solution services, Longsys collaborates with upstream storage wafer fabs to jointly propose a transformation from the traditional product sales model to a TCM (Technologies Contract Manufacturer, Technology Contract Manufacturing) cooperation model. upgrade.

Under the traditional sales model, storage module manufacturers first purchase wafers from the original storage factory, and then sell them to end customers after going through R&D, design, packaging, testing and manufacturing. The complexity of the intermediate links between the upstream original manufacturers and downstream end customers has led to "disconnections" in communication, and it is also difficult to efficiently match the downstream application market's demand for diversified, customized, and innovative storage products. Module factories also need to purchase large amounts of wafers from original factories in advance for reserve, and face challenges such as huge price fluctuations brought about by the industry cycle.

The TCM (Technical Contract Manufacturing) cooperation model enables efficient and direct supply and demand information communication between upstream storage wafer original manufacturers and downstream Tier1 core customers. Based on deterministic supply and demand contracts, Longsys focuses on the advantages of the storage solution service platform and integrates storage master control , firmware custom development, high-end packaging and testing technology, after-sales service, brand and intellectual property and other capabilities, based on the product needs of upstream storage wafer fabs or downstream Tier1 customers, we can efficiently complete one-stop delivery of storage products. This will improve the efficiency and effectiveness of the storage industry chain from original factories, product development, packaging and testing, product manufacturing to industry applications.

The TCM model aims to create a new anchoring relationship between supply and demand, upgrading the collaborative operation of the industrial chain from the traditional "one-way simplex mode" to a "two-way duplex mode". Under this mode, the original factory can communicate with downstream Tier 1 in a more timely manner Customers conduct information docking, observe real market demand, plan production capacity and resource pricing according to market demand, and focus more on wafer process innovation and production capacity improvement in terms of technology investment, while Longsys will focus on subsequent storage product research and development, customer customization, Integrate packaging, testing, manufacturing and delivery. At the same time, downstream Tier 1 customers can obtain a stable supply of storage resources and the opportunity to deeply participate in the pricing mechanism based on the aforementioned docking and exchange mechanism with the original manufacturer. Longsys will focus on providing customers with more flexible, open, transparent and innovative customization Store products and services to optimally meet the business demands of original manufacturers and Tier1 customers.

As a leading domestic semiconductor storage brand enterprise, Longsys can provide comprehensive industry services throughout the entire chain from memory chip research and development to packaging, testing and manufacturing, and has industrial advantages and accumulation in multiple dimensions such as technology, manufacturing, services, intellectual property, quality, and capital. , has enough strength to integrate the complex intermediate links from upstream original manufacturers to downstream applications, while assisting and serving original manufacturers to improve their operating efficiency, flexibility and customer satisfaction, while jointly providing more stable storage for downstream application Tier1 end customers Resource supply guarantee, more flexible product customization and technical support, and more complete comprehensive services, thereby opening up multiple links in the value chain, jointly building storage resource transparency, technology manufacturing value, comprehensive service customization, and maximizing delivery efficiency. transaction costs minimized

A new cooperation ecosystem to enhance the comprehensive competitiveness of the storage industry.

Customized business operates independently

Service precise focus

Cai Huabo pointed out that Longsys’ original traditional customization and sales business will be fully undertaken and independently operated by Mestor, a wholly-owned subsidiary, to further optimize the company’s overall business layout and achieve multi-point collaboration and efficient development. . Maxdu Electronics focuses on the R&D, manufacturing and sales of general-purpose memories. It has diversified product lines and independent manufacturing capabilities, and provides professional and efficient OEM/ODM/DMS storage services to domestic and foreign customers.